The video is loading...

Highly dynamic, high-precision and high-performance drives are essential wherever heavy external loads need to be moved quickly and positioned exactly.

-

Properties & technical data

Properties & technical data

-

Benefits & areas of application

Benefits & areas of application

-

Digital motor and data integration

Digital motor and data integration

-

MOVIKIT® software modules

MOVIKIT® software modules

-

Functional safety

Functional safety

-

Further options

Further options

-

Product labels

Product labels

Properties standard version

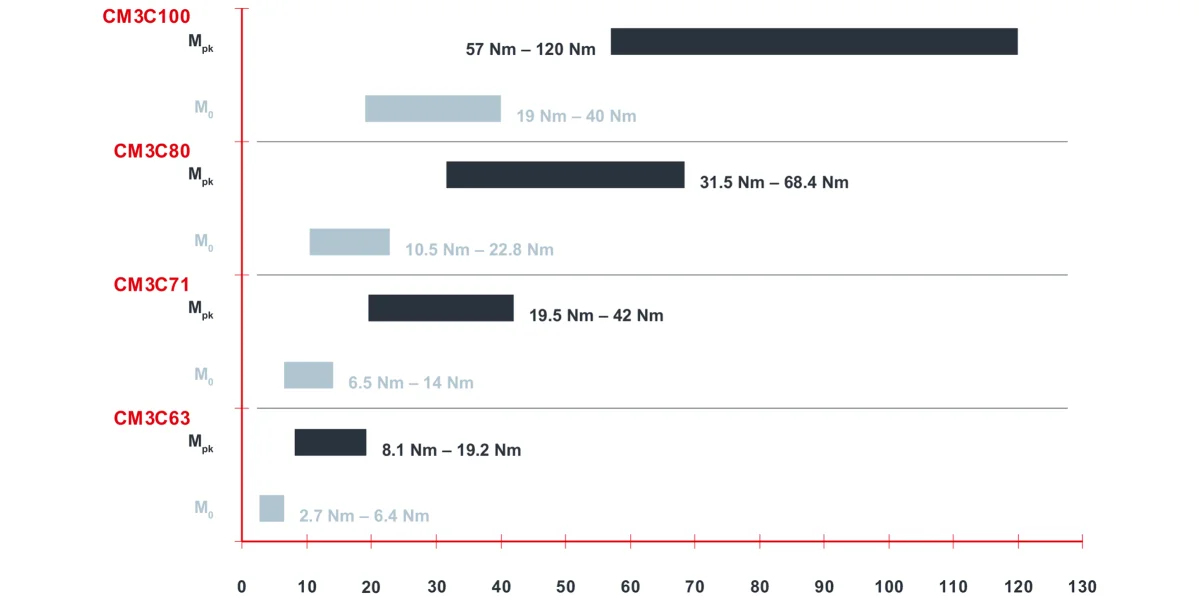

- Four sizes – 63, 71, 80 and 100 – in three lengths – S, M and L

- Compact and powerful thanks to cutting-edge magnet and winding technology

- RH1M resolver

- Adjustable right-angle flange sockets

- PK temperature sensor (PT1000)

- IP65 degree of protection

- Long bearing service life

- High permitted overhung loads

- Stand-alone servomotor or direct gear unit mounting

- Virtually no perceptible cogging

- Continuous standstill torques (M0) from 2.7 to 40 Nm

- Maximum torques (Mpk) of up to 120 Nm

- Up to four speed classes: 2000 min-1, 3000 min-1, 4500 min-1and 6000 min-1

- Condition monitoring and extensive options for fault diagnostics with the MOVILINK® DDI digital motor interface

- Optimized operation on MOVIDRIVE® inverters from the MOVI‑C® modular automation system

Selected technical data

| Motor | Continuous standstill torque M0 Nm |

Dynamic limit torque Mpk Nm |

Weight kg |

Mass moment of inertia Jmot 10-4 kgm |

Speed class rpm |

|---|---|---|---|---|---|

| CM3C63S CM3C63M CM3C63L |

2.7 4.9 6.4 |

8.1 14.7 19.2 |

3.16 4.51 5.85 |

1.3 2.5 3.6 |

3000 4500 6000 |

| CM3C71S CM3C71M CM3C71L |

6.5 9.5 14 |

19.5 28.5 42 |

6.42 7.87 10.7 |

7.4 10.7 17.1 |

2000 3000 4500 6000 |

| CM3C80S CM3C80M CM3C80L |

10.5 15.6 22.8 |

31.5 46.8 68.4 |

10.6 13 18 |

17.6 25.2 40.6 |

2000 3000 4500 6000 |

| CM3C100S CM3C100M CM3C100L |

19 26.8 40 |

57 80.4 120 |

16.5 20.2 27.7 |

40 57.3 92.1 |

2000 3000 4500 |

The benefits for you

- Space-saving installation

thanks to a small size, a compact design and direct gear unit mounting without adapters or couplings - Fast, reliable startup

with auto-tuning using the electronic nameplate - Less installation work

as a result of using motors with simple and cost-saving single-cable technology

- Suitable for foodstuff applications

thanks to a dirt-repellent, hygiene-friendly design - Safe deceleration of heavy loads

using powerful spring-loaded brakes with increased working capacity - Optimum drive selection

thanks to our unique and versatile modular system

The CM3C.. series is highly versatile

- Heavy-duty gantries

- Cartesian robots

- Palletizers

- Deep drawing and forming machines

- Dynamic removal and loading units

- Machine tools

- Hoist applications

- Materials handling technology with heavy external loads

Materials handling technology/intralogistics

Hoist applications

Ohne Getriebe nur die halbe Lösung?

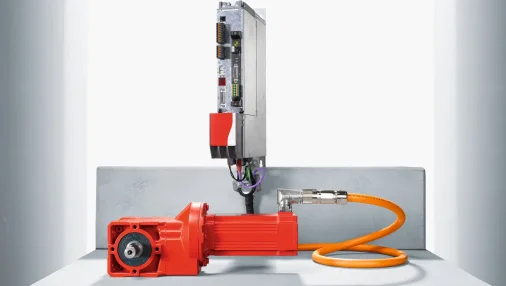

Only half the solution without a gear unit? Not with SEW‑EURODRIVE's modular system! You can opt to combine the CM3C.. series servomotor with a helical, parallel-shaft helical, helical-worm, helical-bevel or SPIROPLAN® gear unit, or with a servo planetary gear unit from the PxG series.

Digital motor and data integration

The video is loading...

Simple and fast motor startup with MOVILINK DDI

is possible thanks to the MOVILINK® DDI digital interface. It's all based on single-cable technology. In fact, motors and inverters from the MOVI‑C® modular automation system require just one hybrid cable for power supply and data transfer. The hybrid cable supplies the motor with power and MOVILINK® DDI, a digital encoder, transfers all necessary power, brake and diagnostic data between inverter and motor. This saves you both time and money during installation and startup.

The digital motor and data integration works with synchronous motors, asynchronous motors and decentralized drive technology.

MOVIKIT® ready-to-use software modules are suitable for everything from simple drive functions through to complex motion control functions. Our goal is added value for you, shortening startup times considerably by providing configurable automation and motion control functions.

Examples of various MOVIKIT® software modules:

MOVIKIT® Robotics

MOVIKIT® Robotics includes MOVIKIT® software modules for robot control.

MOVIKIT® MultiAxisController

The MOVIKIT® MultiAxisController includes MOVIKIT® software modules for central control of any number of mechanically coupled drives.

Functional safety overview

- You can also request motors from the CM3C.. series with a safety brake and safety encoder. These can be integrated into the servomotor individually or in combination.

- The following safety functions are possible with the safety brake:

- SBA (Safe Brake Actuation)

- SBH (Safe Brake Hold)

- Using safety encoders, safety functions relating to rotational speed, direction of rotation, standstill and relative position are possible, such as SS1, SS2, SOS, SLA, SLS, SDI and SLI to IEC 61800‑5-2.

Available options

- Forced cooling fan for enhanced thermal motor capacity utilization

- Terminal box

- Safety-rated design with brake and encoder

- Explosion-protected design: ATEX and IECEx (in preparation)

- All standard approvals (UL, CSA, EAC, UkrSEPRO, CEL and CMIM)

- Optional encoder systems:

- HIPERFACE® encoder with electronic nameplate

- Two-cable technology

- Scalable (128/1024 sin/cos)

- Single-turn and multi-turn

- Encoderless design with hybrid plug connector

- Single-cable technology

- MOVILINK® DDI digital encoder interface

- Single-cable technology

- Scalable (12 bit / 18 bit)

- Single-turn and multi-turn

Compatible non-SEW encoder systems

- DRIVE‑CLiQ from Siemens for operation using standard Siemens Sinumerik and Sinamics controllers

- EnDat2.2 from HEIDENHAIN

- HIPERFACE DSL from SICK Stegmann

Certifications / Conformity

- CE (European Economic Area)

- CEL (China)

- CMIM (Morocco)

- UL-approved (USA and Canada)

- EAC (Customs Union of Russia, Kazakhstan and Belarus)

- UKCA (United Kingdom)

- UA.TR. (Ukraine)

Configure your customized product

- Detailed information about your customized product

- CAD data and documentation for your configuration

- Option to directly request a quotation or place an order

Find out more

Data and documents

Operating instructions, catalogs, brochures and lots more! All technical data about CM3C..