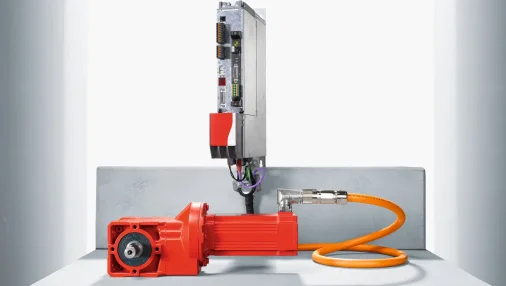

MOVIGEAR® performance

The video is loading...

MOVIGEAR® drive unit performance

Configure your customized product

- Detailed information about your customized product

- CAD data and documentation for your configuration

- Option to directly request a quotation or place an order

FIND OUT MORE

Data and documents

Operating instructions, catalogs, brochures and lots more! All technical data about MOVIGEAR® performance