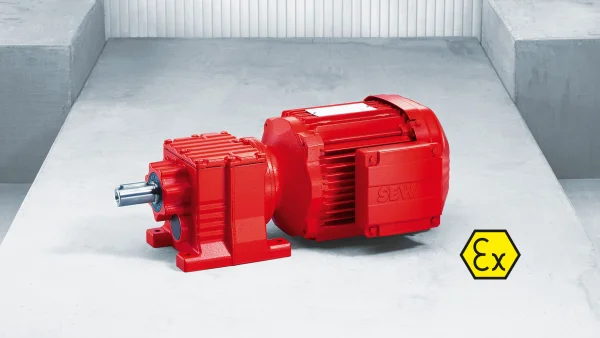

Choose from 21 sizes of gear units for use in potentially explosive atmospheres. Our helical gear units in II2GD version are the ideal combination of performance and low space requirements.

The classic: Versatility and performance, even in potentially explosive atmospheres

Our explosion-proof helical gear units have equipment group II approval for categorie 2. They drive systems and machines in potentially explosive atmospheres.

A total of six single-stage and 15 two and three-stage sizes cover a performance range of 50 Nm to

The R gear units also meet demands for high output speeds and light weight, of course. With a consistently high level of efficiency, our explosion-proof helical gear units offer an optimum ratio between torque output and installation space.

Only half the solution without a motor? Then use our sophisticated modular concept and combine the explosion-proof gear units of the R series with the explosion-proof motor of your choice.

RX / R / RM series explosion-proof helical gear units

- Gear units comply with directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX), equipment group II, categorie 2, variant II2GD

- For use on the European market

- Accepted in China

- Accepted in Russia in combination with EAC certificates (formerly GOST-R)

- Certified protection types:

- Protection type “c”: Protected by safe construction (design safety), EN13463-1 and -5

- Protection type “k”: Protected by liquid immersion, EN13463-1 and -8

- All screws are secured against automatic loosening

- Gear unit has a separate nameplate

- High-quality oil seals

- Lubricant can withstand high temperatures

- Single or multi-stage

- Foot- or flange-mounted

- Foot- and flange-mounted

- Flange-mounted with extended bearing hub

Configure your individual product

- Detailed information about your individual product

- CAD data and documentation for your configuration

- Option to directly request a quotation or place an order

Your benefits

-

Comprehensive offer

as the gear units offer finely stepped torques and gear ratios for use in potentially explosive atmospheres. -

Easy combination

because you can easily combine an explosion-proof helical gear unit with an explosion-proof motor from our modular system.

Explosion-proof RX series (single-stage)

Explosion-proof RX series (single-stage)

Features

Technical data

Sizes 57 / 67 / 77 / 87 / 97 / 107

| Gear unit ratio | i | 1.30 – 8.65 |

|---|---|---|

| Max. output torque |

Nm | 69 – 830 |

| Motor power range (Mounting via AM motor adapter) | kW | 0.12 – 45 |

Areas of application

- Applications in potentially explosive atmospheres with air/gas or air/dust mixtures according to directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX)

- Applications with equipment categories II2GD

- Use with air mixtures

- With gases (G): in zones 1 and 2

- With dusts (D): in zones 21 and 22

- Examples:

- Roller conveyors

- Belt conveyors

- Chain conveyors

Explosion-proof R series (two-stage and three-stage)

Features

Technical data

Sizes 07 / 17 / 27 / 37 / 47 / 57 / 67 / 77 / 87 / 97 / 107 / 127 / 137 / 147 / 167

| Gear unit ratio | i | 3.21 – 289.74 |

|---|---|---|

| Gear unit ratio – double gear units |

i | 90 – 27 001 |

| Max. output torque | Nm | 50 – 18,000* |

| Motor power range (Mounting via AM motor adapter) | kW | 0.09 – 160 |

|

||

Areas of application

- Applications in potentially explosive atmospheres with air/gas or air/dust mixtures according to directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX)

- Applications with equipment categories II2GD

- Use with air mixtures:

- With gases (G): in zones 1 and 2

- With dusts (D): in zones 21 and 22

- Examples:

- Rotary tables

- Pumps and fans

- Waste water and sewage treatment plants

- Fans

- Roller conveyors

- Belt conveyors

- Chain conveyors

- Corner transfer units

Explosion-proof RM series (two-stage and three-stage)

Features

- Fifteen frame sizes allow for an optimum ratio between performance and space requirements

- Finely stepped gear unit ratios up to i = 289.74; or i = 27,001 for double gear units

- Available in foot or flange-mounted design

- Also available with reduced backlash

Technical data

Sizes 07 / 17 / 27 / 37 / 47 / 57 / 67 / 77 / 87 / 97 / 107 / 127 / 137 / 147 / 167

| Gear unit ratio | i | 3.21 – 289.74 |

|---|---|---|

| Gear unit ratio – double gear units | i | 90 – 27 001 |

| Max. output torque | Nm | 50 – 18,000* |

| Motor power range (Mounting via AM motor adapter) | kW | 0.09 – 160 |

|

||

Areas of application

- Applications in potentially explosive atmospheres with air/gas or air/dust mixtures according to directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX)

- Applications with equipment categories II2GD

- Use with air mixtures:

- With gases (G): in zones 1 and 2

- With dusts (D): in zones 21 and 22

- Examples:

- Rotary tables

- Pumps and fans

- Waste water and sewage treatment plants

- Fans

- Roller conveyors

- Belt conveyors

- Chain conveyors

- Corner transfer units